PALLET NAILING MACHINES

Easily adjustable to fit your needs.

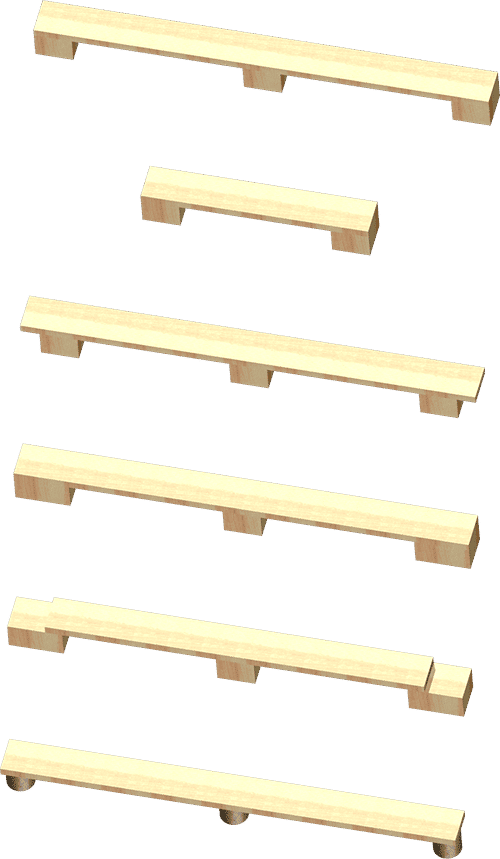

LEG MACHINE OM-1000

- Semi-automated nailing machine for pallet legs.

- 1 machine operator

- 12 legs/min

How does it work?

The magazines are manually fed with blocks and boards where after the machine automatically nails the parts together. The machine is equipped with three channels for blocks and a magazine for boards.

Easily adjustable

It’s easy to produce various types of pallet legs with OM-1000. The machine has three channels for inserting blocks. The cassettes in the channels are changed in order to fit the size of the blocks. The cassettes are easy and fast to readjust.

Mychrome has various additional machinery that can easily be docked on to existing machines in order to build a longer line where more stages can be automated. The possibility to modify the design and the size of the pallets is still available with the additional machinery.

SPECIFICATION MACHINE

Machine specification

Standard performance

Operators

1

Length

2,0 m

Width

2,5 m excluding platform ladder

Height

3,6 m

Power

Electric: 6 kW, 3x400 V+N, Hydraulic: 15 kW, 3x400 V+N

Pneumatic system

7 bar compressed dried air: 300 L/min

Should be filled and controlled

Container for lubricating oil

Machine capacity

12 legs/min

Standard equipment

3 channels with motorized adjustment

3 cassettes, manually adjustable for block sizes

1 cassette, manually adjustable for board length

Operators terminal for production control

Program for saving nail positioning

Nailing system

Electric or hydraulic beam nailing, 1 nail box (9 nails), 9 nailing hammerheads, Individual nail picking, nail indication system

SPECIFICATION MATERIAL

Matrix material: Blocks

Height

Width

Material

Solid wood or pressed blocks

Dimension

70-100 mm

75-150 mm

Matrix material: Leg boards

Minimum

Maximum

Length

600 mm

1 600 mm

Width

75 mm

150 mm

Thickness

16 mm

28 mm

Matrix material: Assembled legs

Minimum

Maximum

Material

Solid wood or pressed blocks

Length

600 mm

1 600 mm

Width

16 mm

150 mm