PALLET NAILING MACHINES

Easily adjustable to fit your needs.

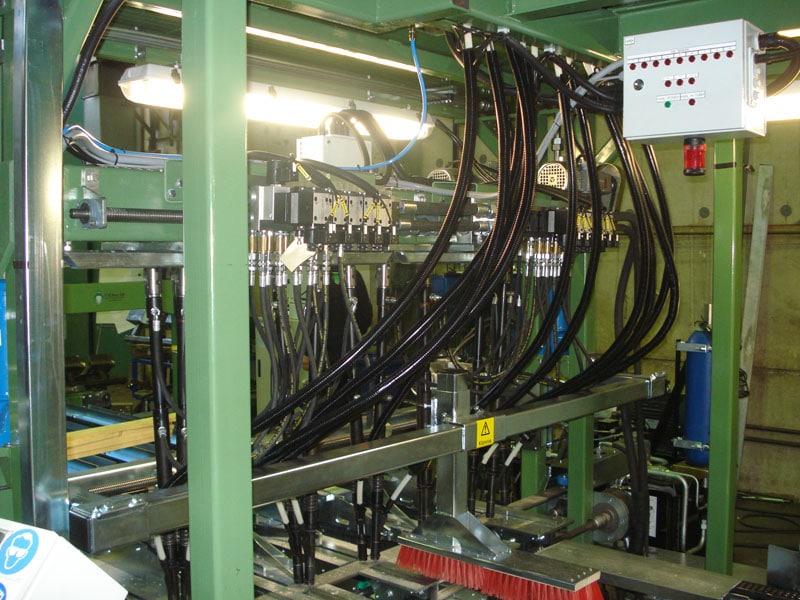

UNDER BOARD NAILING MACHINE UBM-2000

-Fully-automated nailing machine for under boards on stringer pallets.

- 1 machine operator

- 24 boards/min

How does it work?

Two adjustable channels transport the stringer boards into the machine and places them in the right position. The machine nails the stringer boards to the underside of the stringer pallets.

UBM-2000 is designed to work in line with the deck nailing machine REM-2000. The decks are turned upside down by an additional component called FLP turner and automatically fed into the UBM-2000 where the stringer boards are provided with under boards.

SPECIFICATION MACHINE

Machine specification

Standard performance

Operators

1

Length

4 m

Width

2,5 m excluding platform ladder

Height

3,6 m

Power

Electric: 12 kW, 3x400 V+N, Hydraulic: 20 kW, 3x400 V+N

Pneumatic system

7 bar compressed dried air: 300 L/min

Should be filled and controlled

Container for lubricating oil

Machine capacity

24 boards/min

Standard equipment

2 channels with motorized adjustment

2 nailing supports for stringer pallets

Program for saving nail positioning

Operators terminal for production control

1 nailing support for stringer pallets fixed in middle

Nailing system

Hydraulic or electric nailing, 1 nail box (12 nails), 12 nailing hammerhead, 12 indication system, 12 individual nail pickers

SPECIFICATION MATERIAL

Material: Stringers

Minimum

Maximum

Length

600 mm

1 400 mm

Width

30 mm

100 mm

Height

60 mm

100 mm

Material: Top boards

Minimum

Maximum

Length

600 mm

1 600 mm

Width

75 mm

150 mm

Thickness

16 mm

28 mm

Stringer pallet size

Minimum

Maximum

Length deck & legs

600 mm

1 600 mm

Width deck

600 mm

1 400 mm

Material: Second side board

Minimum

Maximum

Length

600 mm

1600 mm

Width

75 mm

150 mm

Thickness

16 mm

28 mm

Wing on top board

-20 mm

+80 mm