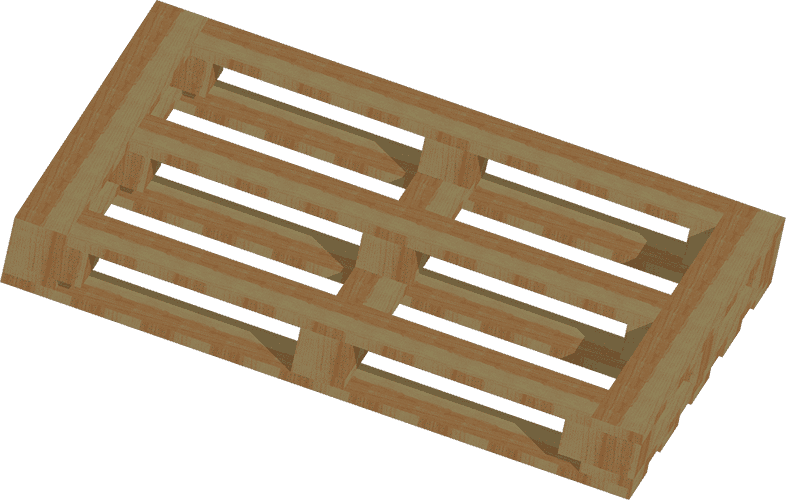

棧板打釘機

可依您的需求,調整相當簡單

PEM-2000 HYD田字型油壓式棧板組合機

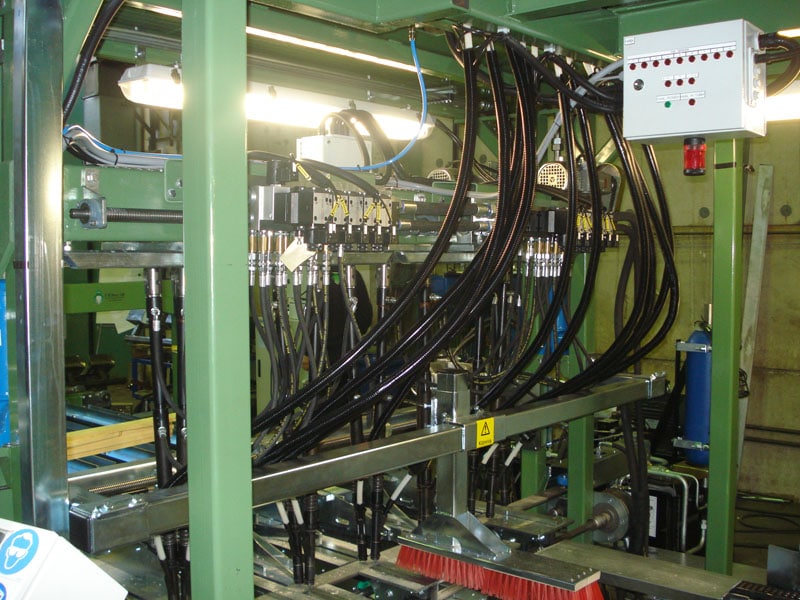

- 全自動油壓田字型棧板釘合機。

- 1 名機器操作員

- 12 次釘合/分鐘

機器運作方式

棧板以棧板腳朝上的方式送入本機。側邊橫向輸送帶會輸送桁板,接著本機會自動將組件安排於正確位置上,以進行釘合。本機以油壓方式釘合田字型棧板。

可方便調整

在所有Mychrome機器上,只需幾分鐘即可修改棧板尺寸和設計的設定。

Mychrome有各種附加機械,可以很容易地停靠在現有機器上,以便建立一條自動化更多步驟的製作線 。附加機械仍可以修改棧板的設計和尺寸。

SPECIFICATION MACHINE

Machine specification

Standard performance

Operators

1

Length

4 m

Width

2,5 m excluding platform ladder

Height

3,6 m

Power

Electric: 12 kW, 3x400 V+N, Hydraulic: 20 kW, 3x400 V+N

Pneumatic system

7 bar compressed dried air: 300 L/min

Should be filled and controlled

Container for lubricating oil

Machine capacity

12 nailings/min

Standard equipment

2 channels with motorized width adjustment

1 hydraulic unit

Program for saving nailing positions

Operators terminal for production control

1 nailing support for perimeter pallets

Nailing system

Hydraulic individual nailing or elecric beam nailing, 1 nail box(12 nails), 12 nailing hammerheads, 12 indication system, 12 individual nail pickers

SPECIFICATION MATERIAL

Material: Legs including blocks

Minimum

Maximum

Material

Solid wood or pressed blocks

Length

600 mm

1 600 mm

Width

75 mm

150 mm

Thickness

70+16 mm

100+22 mm

Material: Decks

Minimum

Maximum

Length

600 mm

1 600 mm

Width

600 mm

1 600 mm

Thickness

16 mm x2

28 mm x2

Pallet size:

Minimum

Maximum

Length deck & legs

600 mm

1 600 mm

Width deck

600 mm

1 600 mm

Wing on perimeter board

Minimum

Maximum

Width direction

0 mm

+20 mm

Length direction

0 mm

+20 mm