棧板打釘機

可依您的需求,調整相當簡單

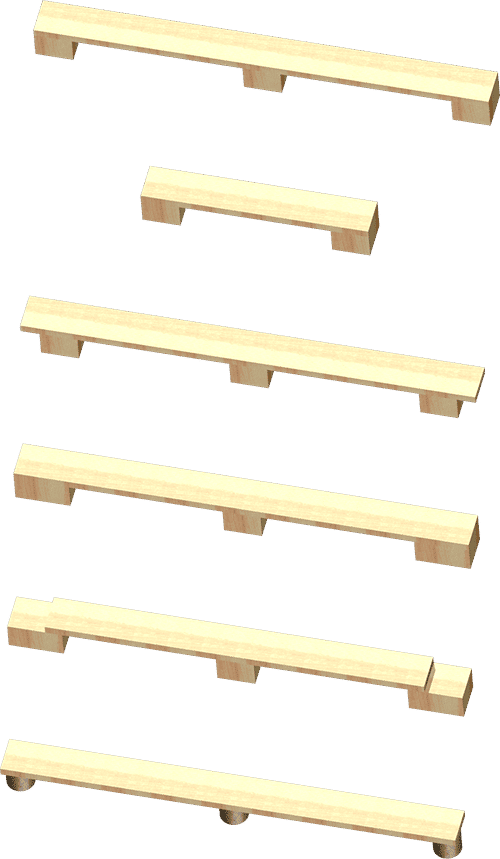

OM-2000HYD油壓式棧板腳組合機

- 半自動棧板腳組合機。

- 1 名機器操作員

- 12 個棧板腳/分鐘

機器運作方式

腳粒經由運輸帶自動送進,底板則送進卡槽。運輸帶將腳粒送至釘合位置。本機能自動將腳粒和底板置於正確位置進行釘合。

可方便調整

使用本機可很輕鬆製作各種尺寸的棧板腳。 調整不同變形相當俐落且迅速。在所有Mychrome機器上,只需幾分鐘即可修改棧板尺寸和設計的設定。

Mychrome擁有多種可輕鬆連接現有機器的附加機械設備,可建立具更多自動化階段的製作線。連接附加機械後仍可修改棧板的設計和尺寸。

SPECIFICATION MACHINE

Machine specification

Standard performance

Operators

1

Length

2,0 m

Width

2,5 m excluding platform ladder

Height

3,6 m

Power

15 kW, 3x400 V+N

Pneumatic system

7 bar compressed dried air: 500 L/min

Should be filled and controlled

Container for lubricating oil

Machine capacity

12 legs/min

Standard equipment

3 channels with motorized width adjustment

3 block stoppers, manually adjusted for blocks position in width

1 cassette, manually adjustable for board length

1 belt conveyor for block infeed

Operators terminal for production control

Program for saving nail positioning

Nailing system

Hydraulic individual nailing , 1 nail box(9 nails), 9 nailing hammerheads, individual nail picking, nail indication system

SPECIFICATION MATERIAL

Material: Blocks

Minimum

Maximum

Material

Solid wood or pressed blocks

Dimension

70-100 mm

75-150 mm

Material: Leg boards

Minimum

Maximum

Length

600 mm

1 600 mm

Width

75 mm

150 mm

Thickness

16 mm

28 mm

Assembled legs

Minimum

Maximum

Length

600 mm

1 600 mm

Width

75 mm

150 mm