PALLET NAILING MACHINES

Easily adjustable to fit your needs.

KOMBI-FLEX R-1000

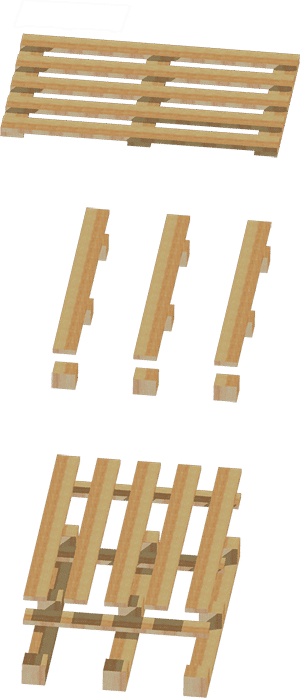

- Semi-automated nailing machine for production of complete pallets in two steps.

- 2 machine operators

- About 500 pallets/8h shift

How does it work?

Blocks and leg boards are fed manually in the left fixture. The machine nails the parts together automatically. The ready-made legs are moved by hand to the right fixture, where deck boards are manually placed on top of the legs and nailed together automatically. Both fixtures run simultaneously. The machine starts by pushing a button and the finished pallets are manually pushed out in the back of the machine.

Easily adjustable

It’s possible to upgrade R-1000 within the 1000 series, with e.g. assembly machine SMS-1000. The settings for the size and the design of the pallets can be modified in just a few minutes on all Mychrome machines.

Mychrome has various additional machinery that can easily be docked on to existing machines in order to build a longer line where more stages can be automated. The possibility to modify the design and the size of the pallets is still available with the additional machinery.

SPECIFICATION MACHINE

Machine specification

Standard performance

Operators

1-2

Length

3,5 m

Width

2,5 m excluding platform ladder

Height

3,6 m

Power

14 kW, 3x400 V+N

Pneumatic system

7 bar compressed dried air: 300 L/min

Should be filled and controlled

Container for lubricating oil

Machine capacity

500 pallets/8h

Standard equipment

1 channel for legs

1 channel for pallet assembly

1 pallet matrix interchangeable

1 leg matrix adjustable

Operators terminal for production control

Program for saving nail positioning

Nailing system

Hydraulic beam nailing, 3 nail boxes, 30 nailing hammerheads

SPECIFICATION MATERIAL